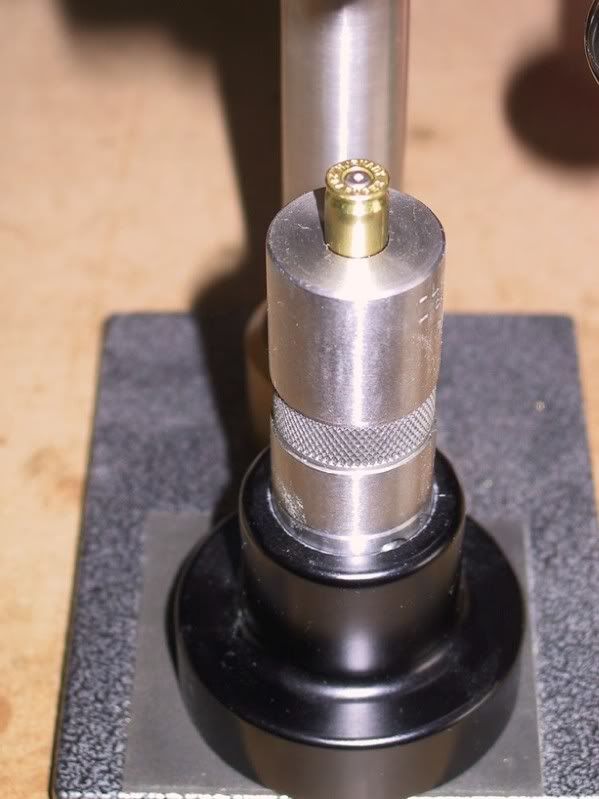

I got my Wilson dies, now it's time for an arbor press.

Any suggestions??

Most of the ones I see are in the roughly $100-$125 range.

This is the one I keep leaning towards:

http://www.21stcenturyshooting.com/New_Gen_Arbor_Press.php

Any suggestions??

Most of the ones I see are in the roughly $100-$125 range.

This is the one I keep leaning towards:

http://www.21stcenturyshooting.com/New_Gen_Arbor_Press.php